High-performance solid tools from "HALTEC" company

HALTEC has been working in Russian tool market since 1993 and today it has got a unique experience in almost all industries.

We offer complex solutions for Metalworking issues:

- Technical solution

- Technological process

- Selection of equipment and tooling

- Tooling system

- Cutting tool

- Complex supply "turnkey"

- Start of production

- Training

- Service maintenance

- Technical support

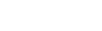

Tooling and accessories, "HALTEC" production

Tooling

- Made for HALTEC

- large product range

- operative delivery

- price-quality ratio

Efficiency

Huge warehouse (more than 800 m2) allows you to create consignment for each client. HALTEC constantly increases inventory, for faster response to requests.

Opportunities

- Consignment

- Creating a warehouse for the client

HALTEC High-performance cutting tool

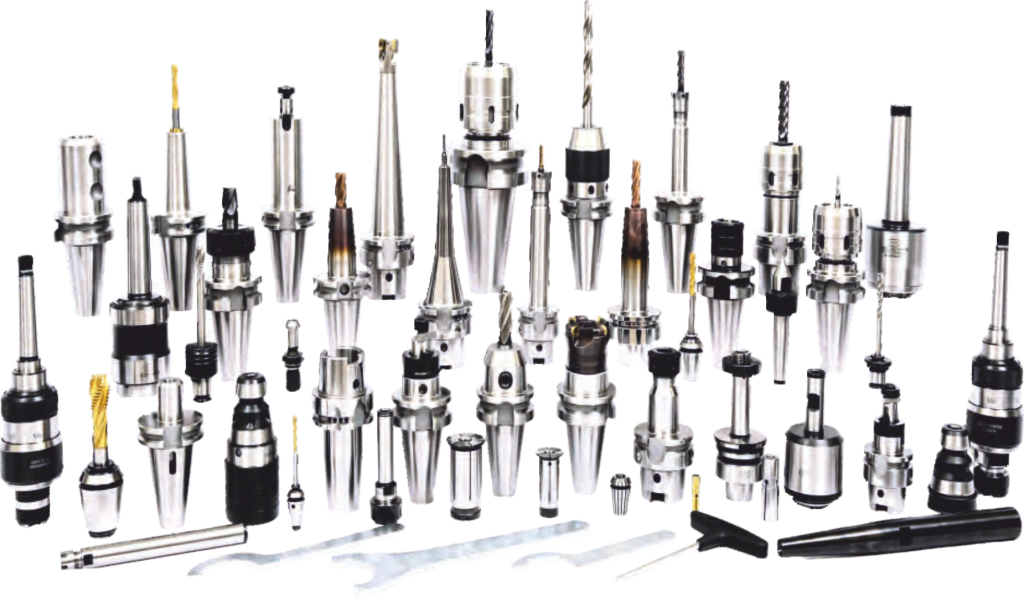

Cutter Mills

- Made for HALTEC

- High flow

- Wear resistance is higher than that of competitors

- Full equipment is already in stock

Innovations

HALTEC always invests in personnel and equipment to meet high requirements of innovations.

Opportunities

- Any sizes on request

- Research work (special solutions)

- • Specialists’ training in the training centre "HALTEC"

Ceramic mills

- Made in Russia

- 12 times faster than carbide tools speed up to 1000 m / min!

- There is no need in coolant, air blowing

Efficiency

Huge warehouse (more than 800 m2) allows you to create consignment for each client. HALTEC constantly increases inventory, for faster reaction on requests.

Opportunities

- Consignment

- Creating a warehouse for the client

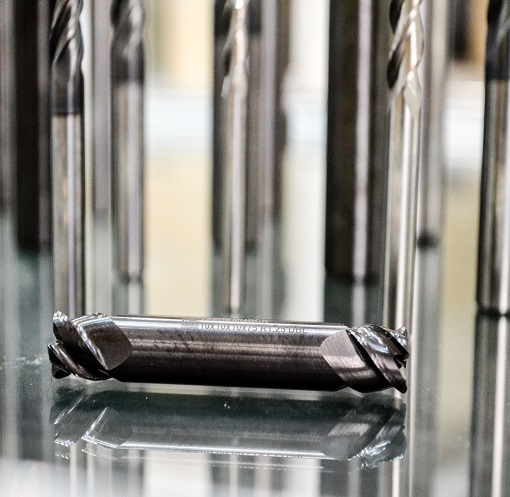

History of HALTEC tools development

HALTEC has produced standard and special solid cutting tools — end mills, drills, reamers, etc. for 7 years. Serial production of solid carbide high-performance mills with a diameter from 3 to 40 mm is mastered. These mills are suitable for different processed materials — from aluminum to titanium and heat-resistant alloys, and also for composite materials and high-strength carbon fiber.

We use only high-quality carbide blanks and develop a unique tool geometry that meets strict international requirements for quality, performance and durability. Оur production is certified according to ISO 9001:2008.

OPPORTUNITY OVERVIEW

-

Patented technology of carbide ceramic mills production provides the best possible results in the treatment of heat-resistant Nickel-based alloys.

-

Solid carbide mills for titanium alloys processing are manufactured with special anti-vibration geometry.

-

Cutter mills RA series with indexable inserts.

-

Tooling and accessories for machines

-

Development of special solutions on request