Development and implementation of product manufacturing technologies

Specialists of the Technology Center "HALTEC" develop technology for processing parts from scratch - starting with studying the drawing, and ending with the control of the finished part.

Stages of engineering work:

• Study of the text of the task

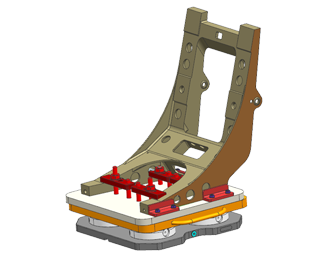

• Creating a mathematical model

of

of

Creating a solid-state mathematical model of the part is the primary step of writing control programs for CNC machines.

We have extensive experience in modern CAD / CAM systems, which allows us to build mathematical models of parts of any complexity level as soon as possible. Before building a model, our specialists analyze the drawings, clarifying controversial issues that take into account the peculiarities of production.

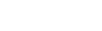

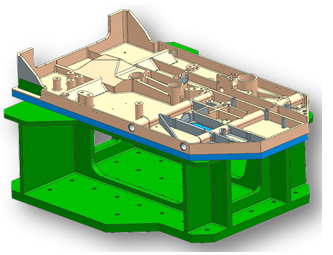

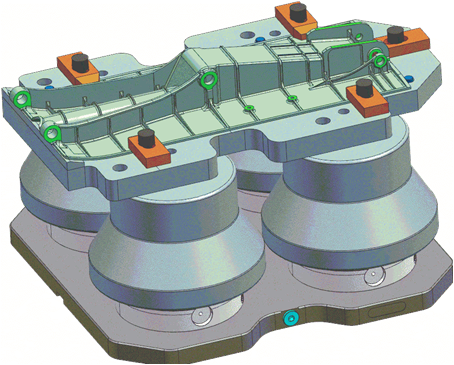

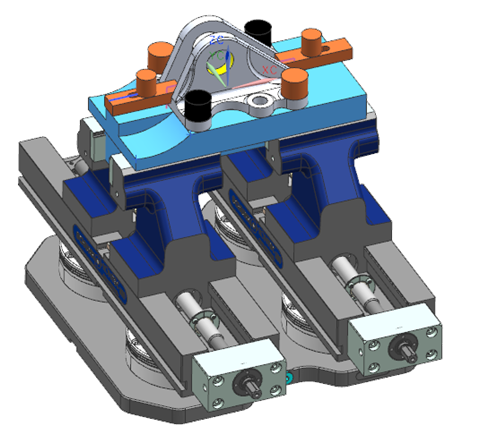

• Tooling design

of

of

In the manufacture of parts on the machine, even with the use of modern multi-axis equipment, it is not always possible to do without the use of technological equipment. For all the technological processes developed by our company, we try to design as much as possible unified technological equipment. To speed up the implementation process, the production of tooling on a CNC machine tool is practiced according to a program, bypassing tool production, where this process can be delayed for a rather long period. An incomparable advantage of this method is the possibility to reduce the time for preparation of production and to process the device in its natural environment for its subsequent use.

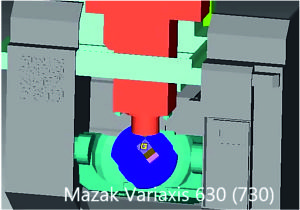

• Development of the post-processor

Specialists of the company "HALTEC" is developing postprocessors and kinematic models of machines of any manufacturers.

The following options are available postprocessor:

-

Model 3 - 5 Axis Virtual Machine

-

Model 3 - 5-axis virtual machine + 1 additional axis

-

Model 3 - 5-axis virtual machine + 1–2 additional axes + spindle model

-

Specialized machine models

-

Supported CAM Systems: Siemens NX10

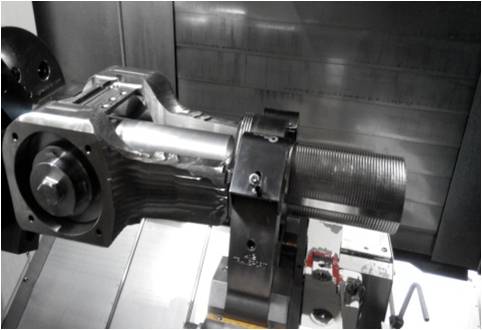

• Writing control programs and manufacturing technology

Our specialists have experience in writing programs in modern CAD systems such as: MAZATROL, Siemens for processing parts of any complexity, using modern tools and mechanical processing methods.

Written by our company UE in conjunction with well-designed technological process to minimize the time of manufacture of parts.

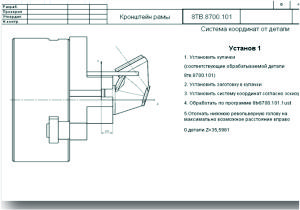

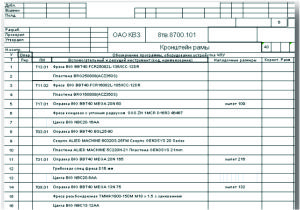

• Development of technical documentation

The projects developed by our company are aimed at reducing the time of manufacturing a part using progressive processing methods. The set of documents of our machining process contains all the necessary information: the installation of clamping devices, adjustment of the cutting tool.

Registration of technological documentation conforms to accepted standards, taking into account the wishes of the host organization.

• Check control programs on the CNC machine simulator

One of the main conditions for the correct operation of the CNC machine is the software that allows control of the UE on the machine simulator. The specialists of our company use the software VERICUT, which simulates the processing on CNC machines in order to detect errors of the control program codes, possible collisions between the machine components and tooling, to identify inefficient areas in the control program.

Thus, we eliminate errors before transferring the program to the machine and avoid the need for manual checking on a CNC machine.

• Testing on the machine

• Final delivery of the test sample to the control

• Serial production

The implementation process is carried out by our specialists at the customer’s premises or on equipment available from our company. At the same time, the correctness of all technological operations related to the adjustment of the machine for the manufacture of the part is monitored, as well as assistance is provided for measuring the introduced part.

According to the results of the implementation, the control program and technology can be adjusted based on the constructive wishes of the customer.

With the serial launch of parts in production, if necessary, will be provided with technological support.