Writing and testing postprocessors for any type of equipment

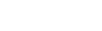

A postprocessor is an additional software module that is developed to convert the machining path calculated in CAD/CAM programs into machine-specific codes.

At modern production facilities, there are many CAD/CAM : Siemens NX, CATIA, CREO, Tebis, etc. with their help, the engineer designs a part, receives a virtual "picture", and the natural question arises: how can the information from this picture be converted into such a data format that your particular machine understands and fulfills them as accurately, safely and efficiently as possible?

This task is solved by an intermediate program-postprocessor, which on the one hand analyzes the data of CAD/CAM system, on the other - takes into account the kinematic and technological features of the machine type. As a result, the postprocessor recodes the virtual image into a file - a working program that is loaded into the appropriate machine for processing. Thus, for EACH type of machine requires the purchase of a postprocessor, and it is for your SPECIFIC CAD / CAM system, as postprocessors of different CAD / CAM products have a completely different implementation.

The postprocessor is a very important component that allows to reduce losses from the "human factor" and improve the efficiency and safety of the use of CNC equipment.

If the postprocessor is written poorly, the programmer is often forced to intervene in the control program manually, and this can lead to an error that can no longer be corrected and which can lead to product defects, and even worse, damage to expensive equipment.

The HALTEC company uses and offers the clients CAD / CAM Siemens NX product as the most widespread and effectively applied on the majority of the hi-tech enterprises of Russia. It is in the environment of this product that our specialists develop, implement and maintain postprocessors for almost all types of CNC equipment.

The functions of the postprocessor are very diverse and go far beyond the simple coding of machine movements by calculated coordinates. In the process of its operation, a number of standard procedures are performed, namely:

* read the entire array of data prepared in the NX environment;

* translation into the coordinate system of the machine, which is an extraordinary task in the case of complex multi-coordinate machines;

* checking the limits (soft limits) of the machine;

* formation of commands for the movement of the working bodies of the machine for all kinds of interpolation (linear, circular, helical, polar, spline);

* formation of commands that ensure the tool change cycle;

* coding of spindle feed and speed values;

* issuing commands to turn on cooling, commands clamps-decompression;

• the purpose of filing subject to the restrictions related to the nature of the movement permitted range of flows, the peculiarities in the modes of acceleration-braking rack CNC;

* formation of commands that provide correction for the radius and length of the tool;

* ensuring the safest approach/departure to the workpiece;

* use of standard cycles of drilling, boring, threading, etc. with the transfer of cycle parameter values from the environment NX;

* diagnostics of errors that can occur due to both incorrect actions of the programmer and limitations in the NX environment;

* output of auxiliary information and comments in the header of the program (approximate processing time, list of used tools, etc.).

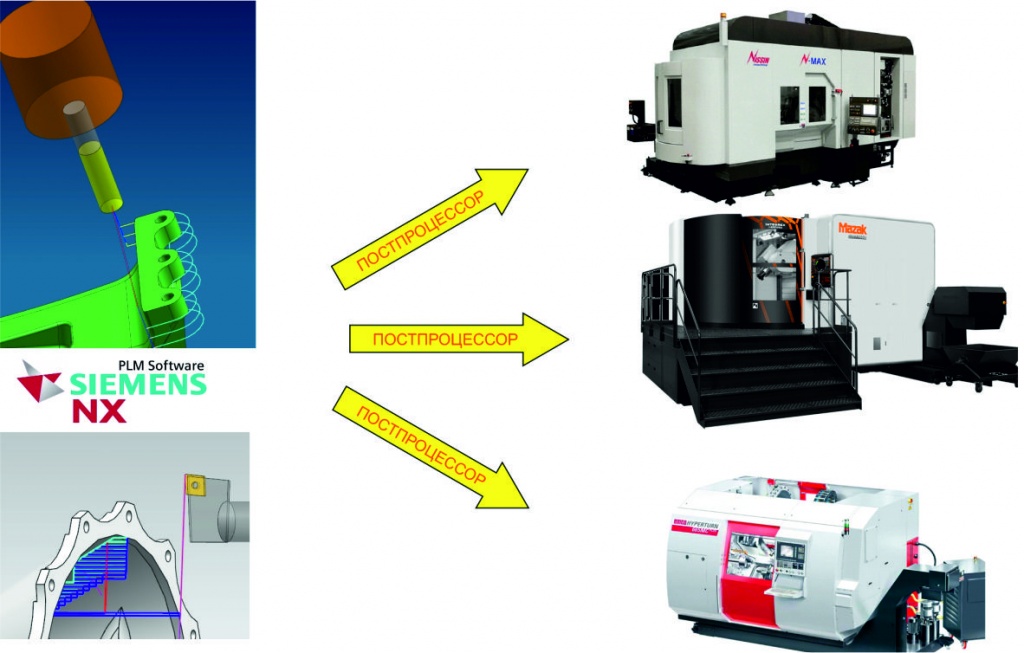

A separate function of the postprocessor is developed to use Renishaw measuring cycles, when a number of auxiliary actions are performed to measure the workpiece, calibrate the tool and zero the part before calling the main processing program. Such programming significantly reduces the operator's time for manual manipulations and measurements, especially in mass production.

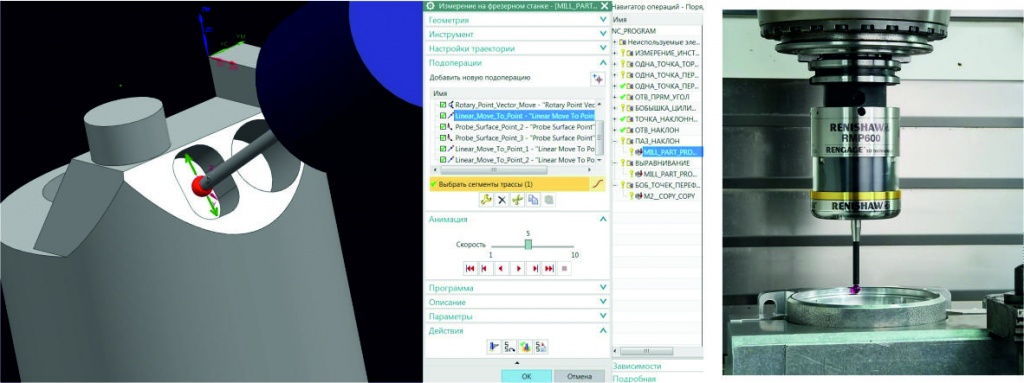

Practice shows that each machine has some individual features:

Practice shows that each machine has some individual features:

• stand version,

• purchased a set of configuration options,

* setting the machine parameters, which is performed both at the factory and during commissioning.

Thus, the behavior of even the same machine model can be significantly different. All this can lead to significant variations in the composition and functionality of the postprocessor.

In addition, additional variability is associated with different versions of the Siemens NX SELF-product.

The HALTEC company has important advantage: being the official representative in Russia of the leading Japanese producer of MAZAK machines, we have available postprocessors for any models of MAZAK machines therefore they can be introduced into production in the shortest possible time.

the process of implementing the postprocessor is carried out in stages:

the process of implementing the postprocessor is carried out in stages:

1) machine parameters are analyzed and adjusted in close cooperation with MAZAK representatives;

2) the basic version of the postprocessor is modified taking into account the previous paragraph;

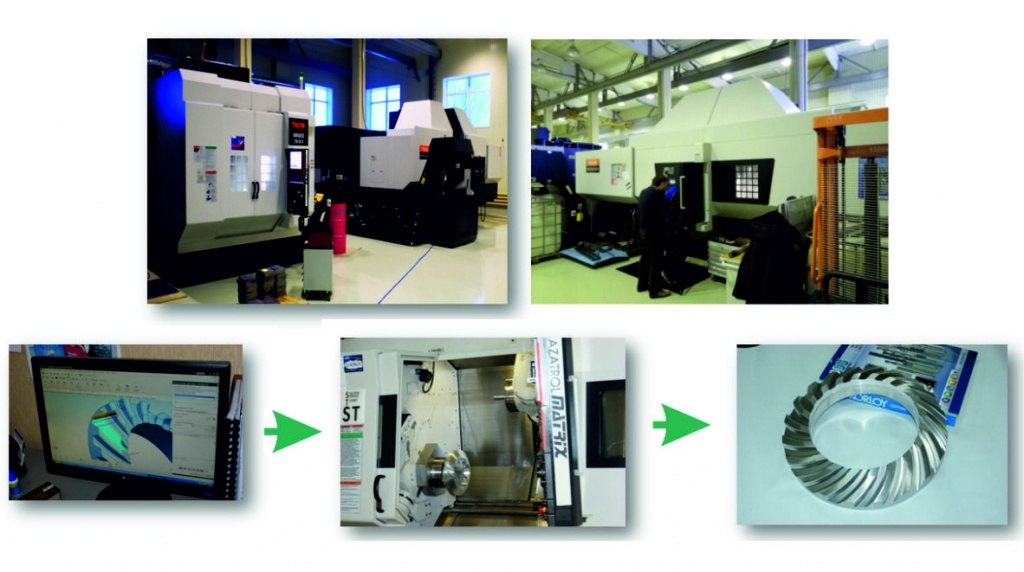

3) the test part is manufactured using various machining operations in the required Siemens NX version;

4) based on the test results, comments are identified, and the postprocessor is again finalized;

sometimes this reveals some defects or under-tuning of the machine, and the work involved Adjusters;

5) training of clients is carried out, and according to its results their wishes are also entered into the postprocessor.

and only after that the transfer of the postprocessor to the customer is performed.

and only after that the transfer of the postprocessor to the customer is performed.

Moreover, the development of a postprocessor is only a relatively short period of testing/delivery/acceptance, but more important is the subsequent support, when the developer quickly and efficiently solves any problems of the client.

The HALTEC company offers not just one-time development of the postprocessor, and complex work of experts-programmers, Adjusters, technologists whose long-term experience gives the guaranteed results.

The maintenance process is not limited to a fixed contractual period, and continues throughout the life cycle of the machine.

Another of our competitive advantages in postprocessors is testing and testing of postprocessors on real equipment in the manufacture of a wide variety of complex parts of customers. Thus, we have a proven software product.

however, the company "HALTEC" is engaged not only in MAZAK equipment, but also introduces advanced Metalworking technologies on machines of other manufacturers throughout Russia. Providing engineering services, we also have the competence to develop postprocessors for other, the most common machines and racks – FANUC, SIEMENS, HEIDENHAIN.

however, the company "HALTEC" is engaged not only in MAZAK equipment, but also introduces advanced Metalworking technologies on machines of other manufacturers throughout Russia. Providing engineering services, we also have the competence to develop postprocessors for other, the most common machines and racks – FANUC, SIEMENS, HEIDENHAIN.

so, today we offer the development of NX postprocessors for CNC equipment of all manufacturers:

so, today we offer the development of NX postprocessors for CNC equipment of all manufacturers:

* 3-axis milling machines (including additional external rotary tables, corner heads, etc.));

• 4-axis milling machines of any layout (horizontal or vertical);

* 5-axis milling machines of any configuration (with rotary tables, rotary heads, gantry, etc.));

* lathes (2 to 4 axes);

* multifunctional turning and milling centers (including dual-channel,

with the spindle/sub-spindle, two processing heads, steady rests, etc.)